When it comes to shipping products, the choice of a cardboard box can significantly impact both cost and effectiveness. According to packaging expert James Miller, "Selecting the right cardboard box is not just about size; it’s about ensuring the safe delivery of your product and optimizing your shipping budget." This insight emphasizes the vital role that cardboard boxes play in e-commerce and logistics, making the selection process a crucial consideration for businesses of all sizes.

In today's market, where customer satisfaction is paramount, the integrity of your packaging can directly influence the perception of your brand. A well-chosen cardboard box not only protects your goods but can also enhance the unboxing experience for your customers. Factors such as box strength, size, shape, and material quality must be carefully evaluated to meet diverse shipping requirements.

Ultimately, understanding how to choose the best cardboard box for your shipping needs can streamline operations and elevate your brand's reputation. By taking expert advice into account and considering the unique demands of your products, you can make informed decisions that benefit your bottom line and satisfy your customers’ expectations.

When selecting the right cardboard box for your shipping needs, understanding your shipping requirements is crucial. Different products vary in size, weight, and fragility, all of which play a key role in determining the most suitable box.

For instance, lightweight items can usually be shipped in standard boxes, while heavier or more fragile products may require sturdier options like double-walled boxes for added protection.

Assessing the dimensions of your product is essential; you want to ensure that the box fits snugly to prevent movement during transit.

Additionally, consider the shipping environment your box will encounter. If your products will be exposed to moisture,

selecting waterproof or moisture-resistant cardboard is advisable. Other factors include the shipping method—whether it’s by ground or air—as this can affect box material requirements due to varying levels of handling and stress.

Custom boxes may also be an option if you frequently ship specialized products, as they can provide a perfect fit and enhance protection, ensuring that your goods arrive at their destination safely and intact.

When evaluating different types of cardboard boxes for your shipping needs, it's essential to consider factors such as durability, size, and the nature of the items being shipped. Cardboard boxes come in various styles, including single-wall, double-wall, and heavy-duty options. Single-wall boxes are suitable for lightweight items, while double-wall boxes provide extra protection for heavier or fragile items. If you're dealing with particularly delicate goods, heavy-duty boxes ensure maximum safety during transit.

Tips: Always measure your items accurately to choose the right box size. An oversized box can lead to movement inside, increasing the risk of damage. Additionally, consider using reinforced corners and edges for extra strength. If your shipment involves a variety of items, using several box types can help provide adequate protection based on each item's fragility and weight. Lastly, don't forget to seal your boxes properly with high-quality packing tape to secure the contents safely.

When it comes to shipping items, the strength and durability of the cardboard box you choose can significantly impact the safety of your goods. To assess a box's strength, consider its material composition, specifically the flute size and wall construction.

Double-walled boxes, for example, offer enhanced stability and can withstand heavier weights compared to their single-walled counterparts. Additionally, look for boxes that meet or exceed industry standards, such as the Edge Crush Test (ECT) and Burst Test, which ensure that the box can handle pressure and impacts during transit.

Durability is another crucial factor, particularly for items that may be vulnerable to moisture or rough handling. Opt for corrugated cardboard with protective coatings if your packages will be exposed to damp conditions. Furthermore, understanding the weight and fragility of your items will help you choose the right box specifications to prevent damage. By carefully evaluating strength and durability standards, you can select the most suitable cardboard box to ensure your goods arrive safely and intact at their destination.

When selecting a cardboard box for shipping, one crucial factor to consider is the size of the box in relation to the items being shipped. According to a report by the International Journal of Shipping and Transport Logistics, using a box that is too large can lead to excessive movement during transit, increasing the risk of damage. Conversely, a box that is too small can cause compression or impact damage. Hence, it's essential to measure your products accurately and choose a box that allows for a snug fit without being overly tight.

Tip: Always measure your items and consider their shape. For irregularly shaped items, a custom-sized box may be more beneficial to ensure protection during shipment. Additionally, consider leaving some space for cushioning materials, which can help absorb shocks and impacts.

Also, consider the weight of your shipment when choosing the box size. The eCommerce Packaging Report indicates that packages exceeding 50 pounds should be shipped in a double-walled box for added strength. This not only protects the contents but also ensures adherence to shipping guidelines, which often specify weight limits for certain box types.

Tip: For heavier shipments, opt for boxes specifically designed for heavy items, as they often feature reinforced corners and durable flaps that provide enhanced protection.

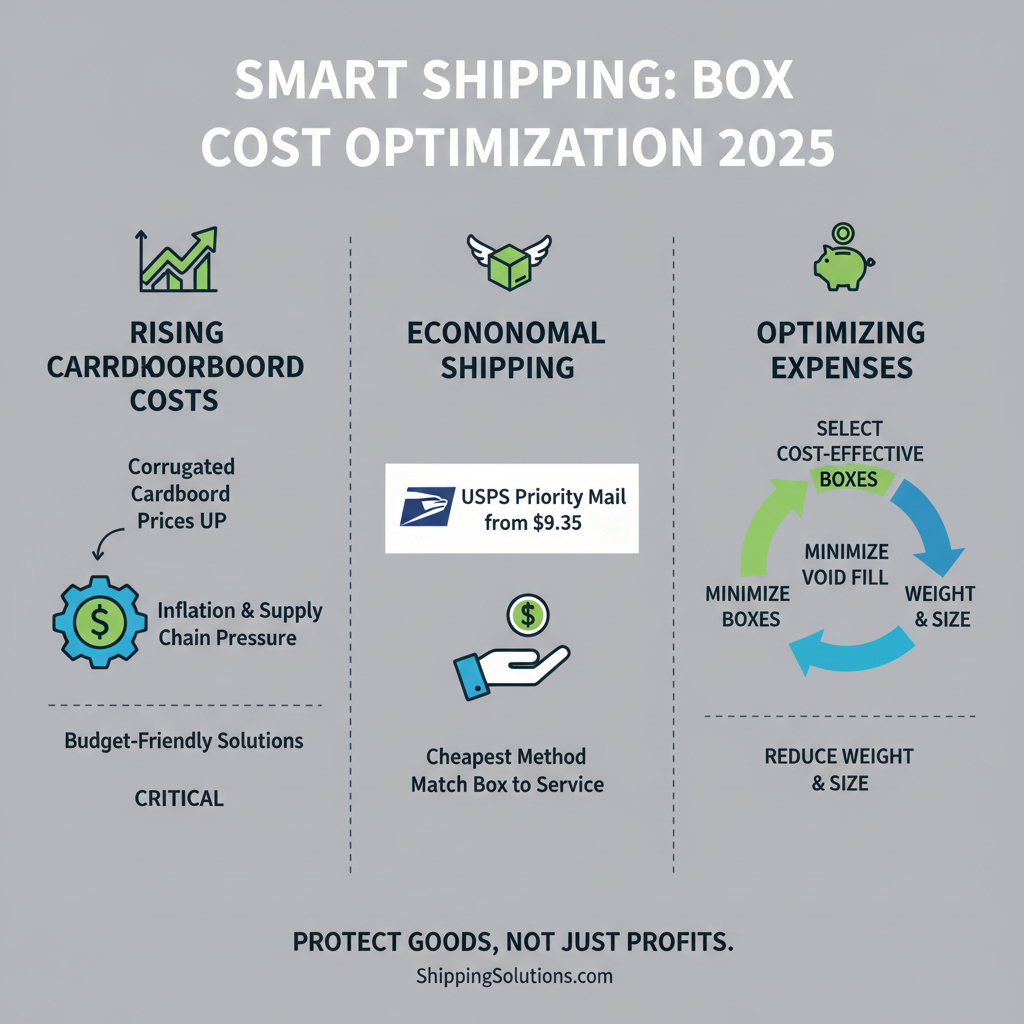

When selecting the best cardboard box for shipping, cost considerations play a critical role in optimizing expenses. The steady increase in the cost of corrugated cardboard has highlighted the need for businesses to identify budget-friendly packaging solutions. In 2025, finding cost-effective options will be paramount as inflation and global supply chain pressures continue to impact pricing. It has been reported that the cheapest shipping method, such as USPS Priority Mail, starts around $9.35, making it essential to match box selection with the most economical shipping service without compromising the safety of the goods.

To maximize savings, businesses should consider the size and design of the cardboard boxes they choose. Smaller and lighter boxes not only reduce material costs but also lower shipping fees. Research indicates that sustainability and affordability are becoming increasingly important to consumers. In 2025, many businesses are expected to favor suppliers who can provide eco-friendly packaging at a competitive price. Therefore, sourcing from local vendors or exploring bulk purchasing options may yield significant savings in cardboard costs while appealing to environmentally conscious consumers.

Tips for optimizing cardboard box selection include utilizing software to calculate dimensional weight pricing, which can help select the most cost-effective box size. Additionally, businesses should explore recycling programs or secondary markets for used cardboard, which can provide substantial cost savings and support sustainability.